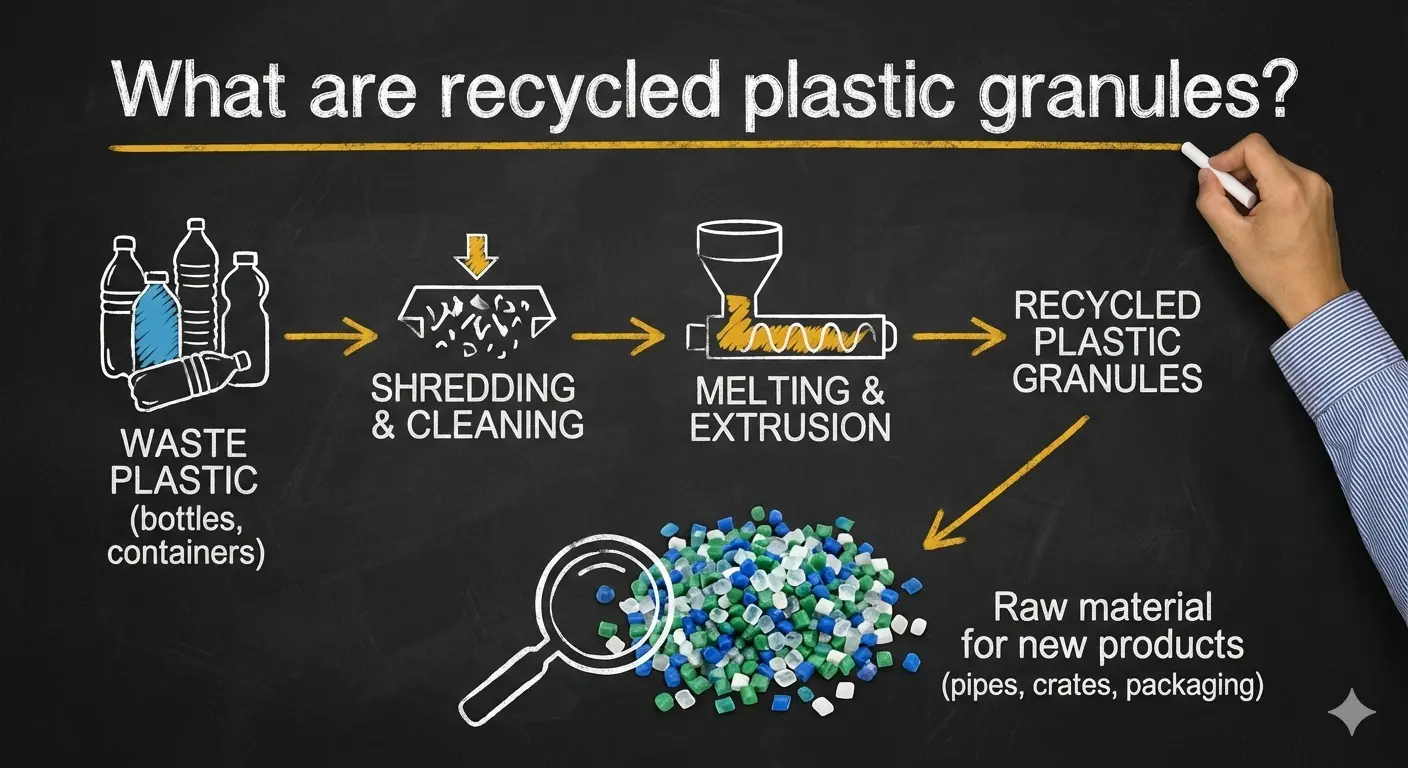

What are recycled plastic granules? Recycled plastic granules are processed plastic materials made from post-industrial or post-consumer plastic waste. They are transformed into small, uniform pellets that can be reused as raw material in plastic manufacturing processes such as injection molding, blow molding, and extrusion. These granules play a crucial role in modern sustainable manufacturing by reducing plastic waste, lowering production costs, and supporting the circular economy.

Today, recycled plastic granules are widely used across industries including packaging, automotive, construction, agriculture, and household goods. With growing environmental regulations and sustainability goals, manufacturers increasingly rely on recycled granules as a reliable alternative to virgin plastic materials.

How recycled plastic granules are produced

The production of recycled plastic granules involves several controlled industrial steps to ensure material quality and consistency.

Collection and sorting of plastic waste

Plastic waste is collected from various sources such as:

- manufacturing scrap

- rejected industrial parts

- packaging waste

- bottles, containers, and films

The collected material is sorted by polymer type, color, and contamination level to ensure uniform processing.

Washing and cleaning process

Sorted plastics undergo intensive washing processes, including:

- cold washing to remove dust and labels

- hot washing to eliminate oils, adhesives, and residues

- friction washing for deep cleaning

This stage is critical to achieving clean and high-quality recycled granules.

Shredding and grinding

Clean plastic materials are shredded into flakes of consistent size. These flakes are then prepared for melting and extrusion.

Melting, extrusion, and filtration

Plastic flakes are melted using single-screw or twin-screw extruders. During extrusion:

- melt filtration systems remove impurities

- metal detectors protect equipment

- degassing systems reduce odors

The molten plastic is then cut into granules.

Cooling and packaging

The granules are cooled, dried, and packaged into:

- 25 kg bags

- 1-ton jumbo bags

They are then ready for industrial use or export.

Types of recycled plastic granules

Recycled plastic granules are produced in different polymer types, each suitable for specific applications.

Recycled polypropylene granules

Polypropylene granules are commonly used for:

- injection molded household products

- automotive parts

- crates and boxes

- woven sacks and raffia products

They offer good rigidity, chemical resistance, and cost efficiency.

Recycled polyethylene granules

Polyethylene granules are available in multiple forms:

- HDPE for rigid containers and drums

- LDPE for flexible films and bags

- LLDPE for stretch and shrink packaging

These materials provide flexibility, durability, and impact resistance.

Recycled polystyrene granules

Polystyrene granules are used for:

- disposable items

- packaging trays

- insulation products

They offer rigidity and ease of processing.

Applications of recycled plastic granules

Recycled plastic granules are used across a wide range of industries.

Injection molding applications

Used to manufacture:

- household items

- caps and closures

- containers

- automotive components

Blow molding applications

Used for:

- bottles

- oil and detergent containers

- industrial drums

Extrusion and film applications

Used to produce:

- plastic films

- shopping bags

- garbage bags

- agricultural sheets

Advantages of using recycled plastic granules

Recycled granules offer several benefits to manufacturers and the environment.

Environmental benefits

- reduced plastic waste

- lower landfill usage

- reduced carbon footprint

- conservation of natural resources

Economic benefits

- lower raw material costs

- stable material supply

- reduced dependency on virgin polymers

Manufacturing benefits

- customizable melt flow index

- consistent quality with proper processing

- suitability for most plastic manufacturing techniques

Quality control for recycled plastic granules

To ensure reliability, recycled granules are tested for:

- melt flow index (MFI)

- density

- moisture content

- ash content

- color consistency

Advanced suppliers provide technical data sheets and batch testing to maintain quality standards.

Role of recycled plastic granules in the circular economy

Recycled plastic granules support the circular economy by:

- extending the life cycle of plastic materials

- reducing environmental impact

- enabling sustainable production models

Governments and industries worldwide are increasingly promoting recycled materials to achieve sustainability targets.

How to choose the right recycled plastic granules

Manufacturers should consider:

- application requirements

- mechanical performance needs

- processing method

- color and appearance

- supplier reliability

Choosing a trusted supplier ensures consistent production and long-term material stability.

FAQs About What are recycled plastic granules?

What are recycled granules?

Recycled granules are small plastic particles produced from processed plastic waste. They are created by collecting, cleaning, melting, and cutting plastic into uniform granules that can be reused as raw material in manufacturing.

What is a plastic granule?

A plastic granule is a small, solid pellet made from polymer materials such as PP, HDPE, LDPE, or PET. Granules are the standard form used by factories because they are easy to transport, store, and melt during production.

What are recycled plastic pellets used for?

Recycled plastic pellets are used to manufacture a wide range of products, including packaging, plastic bags, bottles, pipes, crates, pallets, household items, automotive parts, and construction materials, depending on the polymer type and quality.

What is plastic granulation?

Plastic granulation is the industrial process of converting plastic waste or raw plastic into small, uniform granules. This process usually involves shredding, washing, melting, filtering, and pelletizing the plastic.

How to make recycled plastic granules?

Recycled plastic granules are made by collecting plastic waste, sorting it by type, washing and drying it, shredding it into flakes, melting it in an extruder, filtering impurities, and cutting the melted plastic into granules or pellets.

Why don’t we use plastic pyrolysis?

Plastic pyrolysis is mainly used to convert plastic into fuel, not reusable plastic material. It is expensive, energy-intensive, and eliminates the possibility of recycling plastic into new products, which is why mechanical recycling is preferred for granule production.

What is another name for plastic granules?

Plastic granules are also known as plastic pellets, resin pellets, plastic beads, or polymer granules. All these terms refer to the same small plastic particles used in manufacturing.

How to make bioplastic granules?

Bioplastic granules are produced from renewable sources such as corn starch, sugarcane, or cellulose. These raw materials are processed into biopolymers, melted, and pelletized in a similar way to conventional plastic granules.

How to identify plastic granules?

Plastic granules can be identified by their color, density, melting point, flexibility, and lab testing such as burn tests or infrared spectroscopy. Proper identification is essential to ensure compatibility in manufacturing.

Who buys granulated plastic?

Granulated plastic is bought by manufacturers of plastic products, injection molding factories, film and packaging producers, pipe manufacturers, blow molding companies, and recycling traders worldwide.

Are Coca-Cola bottles really 100% recycled?

Some Coca-Cola bottles are made using 100% recycled PET (rPET) in certain markets, but not all bottles globally are fully recycled. Availability depends on local recycling infrastructure and regulations.

How to make plastic pellets from recycled plastic?

Plastic pellets are made by recycling plastic waste through sorting, washing, shredding, melting, extrusion, and pelletizing. The final pellets are cooled, dried, and packed for industrial use.

Conclusion

Recycled plastic granules are an essential component of modern plastic manufacturing. They provide a sustainable, cost-effective, and versatile alternative to virgin plastics while supporting environmental responsibility. As industries continue to focus on sustainability, recycled plastic granules will play an increasingly important role in global manufacturing and waste reduction.

Polypropylene granules in UAE are the perfect choice for industries seeking high-quality, affordable, and sustainable raw materials. With the UAE’s growing position as a global petrochemical hub, investing in polypropylene is a strategic move that ensures competitiveness in international markets.

We invite you to explore Alarkan Plastic’s wide range of high-quality polypropylene and polyethylene granules.

Our innovative and recycled solutions are designed to support your industries with efficiency and competitive pricing.

Contact us today to learn more about our products or request a customized quotation.

We are here to serve your industrial needs.

Join The Discussion